Unlocking Efficiency: RFID Technology in Returnable Packaging

In the dynamic landscape of returnable packaging, the integration of cutting-edge technologies is reshaping the way businesses manage their supply chains. Among these innovations, RFID (Radio-Frequency Identification) technology stands out as a game-changer, bringing unprecedented efficiency, visibility, and control to the returnable packaging process.

Revolutionizing Traceability and Visibility

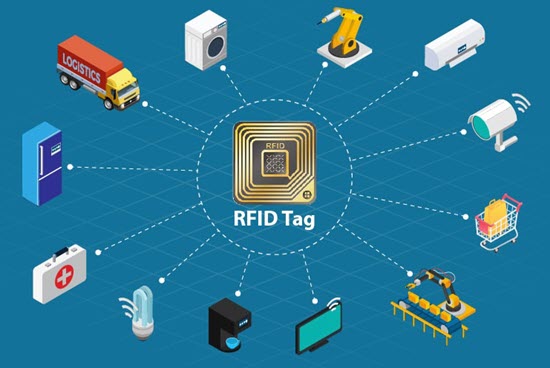

RFID Tags:

At the heart of RFID technology are small yet powerful RFID tags. These tags, equipped with a unique identifier, can be seamlessly embedded into returnable packaging materials. This creates a digital footprint for each item, unlocking a new level of traceability and visibility.

Real-time Tracking:

Imagine having real-time visibility into the location, status, and history of each returnable packaging unit. RFID technology makes this a reality. Whether in transit or at rest, businesses can track their returnable packaging assets with precision, optimizing the entire supply chain.

Efficient Inventory Management Automated Data Capture:

Gone are the days of manual data entry. RFID technology automates the capture of crucial information, eliminating errors and streamlining inventory management. The result? A more accurate, efficient, and time-saving approach to keeping track of returnable packaging stock.

Quick Audits and Counts:

Conducting inventory audits becomes a breeze with RFID. Rapid and accurate counts enable businesses to maintain optimal stock levels, reducing the risk of stockouts and ensuring a continuous flow of returnable packaging materials.

Enhancing Supply Chain Visibility End-to-End Visibility:

RFID provides end-to-end visibility across the supply chain. From the manufacturing facility to the end-user, businesses can monitor the entire lifecycle of their returnable packaging assets. This transparency fosters better decision-making and improved responsiveness to supply chain challenges.

Reducing Loss and Waste:

By having a real-time view of returnable packaging movements, businesses can minimize the risk of loss and waste. Whether due to misplacements or inefficiencies in the supply chain, RFID technology empowers businesses to proactively address issues, ultimately reducing costs.

Streamlining Returns and Reusability Automated Return Processes:

Returning and reusing packaging materials becomes a seamless process with RFID. Automated systems can identify, verify, and process returned items efficiently, expediting the returnable packaging lifecycle.

Condition Monitoring:

RFID technology doesn’t just track location; it can also monitor the condition of returnable packaging units. Businesses can receive alerts for damages or wear and tear, enabling timely maintenance and extending the lifespan of their assets.

Enhanced Customer Experience Accurate Order Fulfillment:

For businesses involved in delivering products in returnable packaging to end customers, RFID ensures accurate order fulfillment. The right products in the right packaging, every time, contribute to customer satisfaction and loyalty.

Bringing Sustainability to the Forefront:

RFID technology aligns seamlessly with sustainable practices. By optimizing the use of returnable packaging through accurate tracking, businesses can reduce environmental impact and contribute to a more sustainable supply chain.

Embracing the Future of Returnable Packaging:

In a world where precision, efficiency, and sustainability are paramount, RFID technology emerges as a beacon of innovation for the returnable packaging industry. As businesses navigate the complexities of modern supply chains, the integration of RFID ensures they do so with unparalleled visibility, control, and eco-conscious practices.

Are you ready to embrace the future of returnable packaging? Explore the possibilities with RFID technology and revolutionize the way you manage your supply chain.

Efficiency Unleashed. Visibility Redefined. Sustainability Achieved.